Time: Popularity:0times

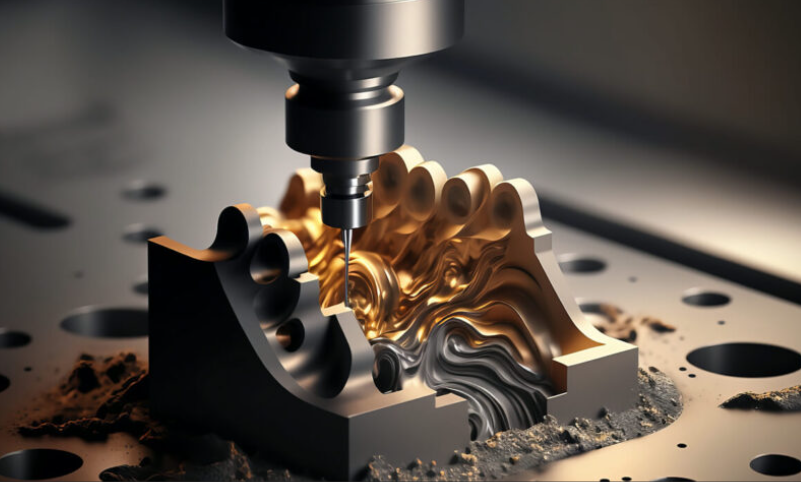

In the industrial world, hardware components—from electrical cabinets to bridge steel structures—bear the brunt of harsh environments, frequent use, and corrosive elements. A reliable coating isn’t just a "cosmetic touch"; it’s a lifeline for product longevity and performance. Hardware powder emerges as a tailored solution, engineered to address the unique pain points of industrial hardware. Unlike generic coatings that struggle with uneven coverage or weak durability, Hardware powder combines precision performance, wide adaptability, and user-friendly application, becoming a trusted choice for manufacturers and engineers alike. Let’s explore why Hardware powder is redefining protection for industrial hardware.

Hardware powder stands out for its ability to solve the most stubborn challenges in hardware coating—problems that generic powders often overlook. Every formula adjustment is rooted in the real demands of industrial scenarios, resulting in three unbeatable strengths.

First, seamless coverage for complex shapes. Hardware components are full of tricky details: welds, corners, and uneven surfaces that traditional coatings often miss. Hardware powder is designed with optimized flowability, ensuring easy powder adhesion on welds and corners—no more "bare spots" that lead to premature corrosion. What’s more, it maintains consistent color across thick and thin workpieces, a critical advantage for assemblies with varying thicknesses. Whether coating a bulky steel beam or a thin electrical cabinet panel, Hardware powder delivers uniform color and finish, eliminating visual inconsistencies.

Second, industrial-grade durability that lasts. Hardware powder’s physical properties are built for resilience. Its pencil hardness reaches ≥2H (per ASTM D3363 and GB/T6739), resisting scratches from tools, transportation, or daily use. Adhesion is top-tier: dry adhesion tests meet ASTM D3359 (5B grade) and ISO 2409 (0 grade), meaning the coating bonds tightly to metal substrates—no peeling or flaking even when the hardware is bent or impacted. Speaking of impact resistance, it achieves ≥50kg.cm (ASTM D2794), withstanding accidental collisions that would damage ordinary coatings. For hardware used in outdoor or chemical environments, its excellent weather and chemical resistance shield against rain, salt spray, and industrial media, extending service life exponentially.

Third, stable performance across conditions. Hardware powder performs reliably in diverse environments: from humid workshops to coastal areas with high salt content, and from freezing winters to scorching summers. It doesn’t fade, crack, or chalk under UV exposure, ensuring hardware retains its protective layer and appearance for years. This stability means less maintenance, fewer replacements, and lower long-term costs for businesses.

Hardware powder’s adaptability makes it a staple across multiple industrial sectors, proving its value in scenarios ranging from small electrical components to large-scale infrastructure.

In electrical cabinets and control panels, Hardware powder is indispensable. These components house sensitive electrical equipment, so corrosion and moisture damage are major risks. Hardware powder’s dense protective layer blocks moisture and dust, while its scratch resistance keeps cabinet exteriors looking neat—even in busy factories where tools or materials bump against them. A manufacturer of industrial control panels switched to Hardware powder and reported a 70% drop in warranty claims related to corrosion or coating damage.

For steel structures and bridges, Hardware powder’s weather resistance shines. Outdoor steel is constantly exposed to rain, wind, UV rays, and (in coastal areas) salt spray. Traditional coatings often peel within a few years, but Hardware powder’s anti-corrosion and UV-resistant properties keep bridges, railings, and building steelwork intact. A municipal bridge project using Hardware powder found that after years of exposure to harsh weather, the steel components showed no signs of rust or coating degradation, reducing maintenance costs by 40%.

Mechanical equipment and industrial hardware also benefit greatly. Machine tool enclosures, mechanical parts, and industrial fasteners face wear, chemical splashes, and high temperatures. Hardware powder’s chemical resistance and heat stability (compatible with typical industrial operating temperatures) ensure it doesn’t degrade under these conditions. Its impact resistance also protects equipment from accidental bumps during operation or transportation, preserving both function and appearance.

Even in specialized hardware applications—such as heavy-duty fasteners, industrial valves, or steel brackets—Hardware powder adapts. Its customizable formula can be adjusted to meet specific needs, whether extra corrosion resistance for chemical plants or enhanced wear resistance for high-friction parts. This versatility makes Hardware powder a one-stop solution for diverse industrial hardware needs.

Hardware powder isn’t just high-performance—it’s designed to make the coating process smoother, more efficient, and cost-effective, whether for large manufacturers or small workshops.

First, flexible spraying options. Hardware powder works with both manual and automatic spraying equipment, but automatic spraying is recommended for consistency (critical for large batches of hardware). The parameters are easy to master: atomizing air pressure and primary air pressure both around 0.5 bar, spraying voltage 40-90kv. This range is compatible with most standard electrostatic spray guns, so there’s no need for specialized equipment. Unsprayed Hardware powder can be recycled via a proper system, boosting material utilization and reducing waste—an eco-friendly and cost-saving feature.

Second, stable storage and easy curing. Hardware powder has a 12-month shelf life when stored in environments below 30℃. Even after expiration, re-testing can confirm if it’s still usable, minimizing waste. Curing is equally flexible: it can be cured at 200℃ for 12 minutes or 180℃ for 15 minutes (based on workpiece surface temperature), adapting to different production line setups. This flexibility means manufacturers don’t need to overhaul their ovens to use Hardware powder.

Third, simple damage repair. Even careful handling can lead to small scratches on hardware coatings. Fixing them with Hardware powder is straightforward: lightly grind the damaged area, clean it with air, then use a recoating mode with reduced spraying voltage. The repaired area blends seamlessly with the rest of the coating, no visible marks—saving time and avoiding the need for full re-coating. This ease of repair is a huge advantage for maintenance teams and manufacturers alike.

Today’s industrial practices prioritize both performance and responsibility—and Hardware powder delivers on both fronts, meeting global safety and environmental standards.

Safety is a top priority during application. Hardware powder is solvent-free, so it doesn’t release harmful volatile organic compounds (VOCs) during spraying or curing. This protects the health of workers, eliminating the risk of toxic fume inhalation. It’s important to follow basic safety guidelines: avoid eating, drinking, or smoking during spraying, and wear a suitable breathing mask to prevent dust inhalation. For full safety details, manufacturers provide material safety data sheets, ensuring compliance with workplace safety regulations.

Sustainability is another key strength. Hardware powder’s high recyclability (unsprayed powder can be reused) reduces material waste, aligning with circular economy goals. Its solvent-free formula also minimizes environmental impact, complying with international environmental standards such as EU REACH and Chinese GB/T standards. For businesses aiming to reduce their carbon footprint, Hardware powder is a responsible choice that doesn’t compromise on performance.

Additionally, the high durability of Hardware powder contributes to sustainability indirectly. By extending the service life of hardware components, it reduces the need for frequent replacements—saving resources and reducing the environmental impact of manufacturing new parts.

Hardware powder’s excellence isn’t accidental—it’s the result of careful material selection and process optimization, tailored to the unique needs of industrial hardware.

In material selection, Hardware powder uses high-quality resins and pigments that bond tightly to metal substrates. The powder’s specific gravity (1.2-1.8g/cm³) is optimized to ensure good flowability and uniform coverage, even on complex hardware shapes. Rigorous testing ensures every batch meets strict standards: bending tests (ASTM D522: 5mm curvature diameter; GB/T1731: 2mm curvature diameter) confirm flexibility, while cupping tests (ISO 1520, GB/T9753: 5mm depth) ensure the coating doesn’t crack or shed under stress.

Process optimization also plays a role. The powder’s particle size is strictly controlled to ensure consistent atomization during spraying, while the curing process is designed to form a dense, cross-linked film that delivers maximum protection. Every batch of Hardware powder undergoes quality checks for color consistency, adhesion, hardness, and corrosion resistance—ensuring reliable performance across all applications.

Hardware powder is more than a coating—it’s a precision-engineered solution that addresses the core needs of industrial hardware: durability, coverage, ease of use, and sustainability. Its ability to cover complex shapes, resist corrosion and wear, and simplify the coating process makes it a favorite for manufacturers, engineers, and maintenance teams.

From electrical cabinets to bridges, from mechanical equipment to specialized hardware, Hardware powder proves its value in every scenario, reducing costs, extending product life, and minimizing environmental impact. Its user-friendly design and compliance with safety standards make it accessible to businesses of all sizes, while its customizable formula ensures it meets specific application needs.

In a world where industrial hardware must perform reliably in harsh conditions, Hardware powder stands as a trusted partner. It turns ordinary metal into durable, long-lasting components that keep industries running smoothly. Choose Hardware powder, and invest in protection that doesn’t just meet expectations—it exceeds them, safeguarding your hardware and your bottom line for years to come.

If you're ready to take the next step, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com